Counter Rotating Twin Barrel

Ho Hsing's production of twin-screw barrels requires not only advanced design and engineering analysis, but also high-performance materials, precision machining, and strict quality control. Every barrel undergoes high-precision CNC machining, thorough inspection, and heat treatment to ensure consistent quality and performance. With our precise manufacturing process, the clearance between the screw and barrel remains uniform, preventing uneven wear.

Our Counter rotating twin barrel are integrally formed, offering a more cost-effective option compared to Twin barrel elements. These are commonly used in the processing of PVC materials.

We also offer two-section twin-screw barrels. The key difference lies in the high-wear areas, where Sinter Bimetallic liners are used. When wear occurs, only the worn section needs to be replaced-similar to the Twin barrel elementsthus improving maintainability and reducing costs over time.

Production Process

From the initial order, understanding customer needs, then to design and production, we will strictly control every step and ensure to meet the customer's usage conditions and customer production environment requirements.

We also consider any special demands of our customers such as spray welding on the OD of the screw to enhance wear resistance.

In terms of design discussion, we will also stand as a professional perspective to help you prevent the problems that may occur in the future.

Product Features

- Customization: Understanding the different needs of each customer, we provide customized services from design to manufacturing, we can precisely custom-made the product dimensions, materials and features to meet customers' different needs and ensure optimal machining performance.

- Precision: We used advanced manufacturing equipment and technology, also we have 3D coordinate measuring equipment to make sure each product has high precision and consistency.

- Life Span: Our product used high quality material and heat treatment, also we can design the screw according to customer's bad production environment. Through special treatment, provide outstanding corrosion resistance and abrasion resistance, extended product life, customer will not only no worry about the production capacity but also decrease the maintain cost of equipment.

- Total Solution: During the production process, our technical team could directly discuss with the machinist and solve customer's problem to achieve customer's demand. From the material chosen to production, we have over 30years experience and professional consult to ensure production work without any problem.

Standard Size

- Φ 65/2

- Φ 75/2

- Φ 90/2

- Φ 115/2

- Φ 130/2

- Φ 150/2

- Φ 180/2

Specification

| Nitrided Steel | Barrel | Remark |

|---|---|---|

| Material | SACM645 | Daido, Sanyo (Japan) |

| QT Hardness | HRC30 ± 2° | |

| Nitrided Hardness | HV 950-1100 | |

| Depth of Nitrided Layer | >0.5mm | |

| Roughness | Ra 0.1um | |

| Bimetallic Hardness | HRC 58-60 (Bimetallic Liner) | Inserted |

| Bimetallic Thickness | 2mm |

| Bimetallic Alloy | Bimetallic Barrel | ||

|---|---|---|---|

| Material | TCB-12 | TCB-20 | Ni-196 |

| Chemical Composition | Fe-Ni-Cu-B | Fe-Ni, Cu-B, Cr, Mo, V | Ni-Cr-Si-B |

| Hardness (HRC) | 60-65 | 62-68 | 58-60 |

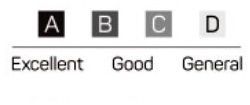

| Abrasion Resistance | B | A | B |

| Corrosion Resistance | C | B | B |

Committed to Quality, Creating Value.

With 40+ years of experience, Ho Hsing has grown from OEM to a full-service company, guided by Japanese experts and driven by advanced technology.

Your Trusted Partner

We stand behind our products and are committed to resolving issues, ensuring full customer satisfaction.

Strict Quality Control

Our products undergo multiple checks during production to ensure accuracy and excellence in the finished results.

Professional Development Team

From OEM to a full company, we know the key components in industry and offer valuable advice to our customers.

Counter Rotating Twin Barrel | ISO 9001 Quality, CMM QC - HO HSING

With over 36 years of experience, HO HSING specializes in manufacturing Counter Rotating Twin Barrel, twin-screws, twin-barrels, and double-pillar hydraulic screen changers. Guided by our commitment to excellence, we provide OEM-quality precision parts with full customization support. ISO 9001–certified and equipped with Mitutoyo CMM from Japan, we ensure zero-defect delivery and complete quality control to boost productivity and cut costs.

Choose HO HSING extruder parts—from twin-screw/twin-barrel replacements to hydraulic screen changer, gear pump, static mixer, die plate, and pelletizing head solutions. As a Taiwan OEM/ODM factory, we offer custom machining, fast lead times, and global shipping—request a quote to optimize plastic extrusion output and reduce downtime.

Since 1984, HO HSING has manufactured high-quality twin-screws, twin-barrels, and double-pillar hydraulic screen changers for plastic extrusion. Backed by advanced technology and 36 years of OEM/ODM experience, we deliver precision extruder parts, full customization, and rigorous quality control to meet demanding production requirements.