Parallel Twin Screw

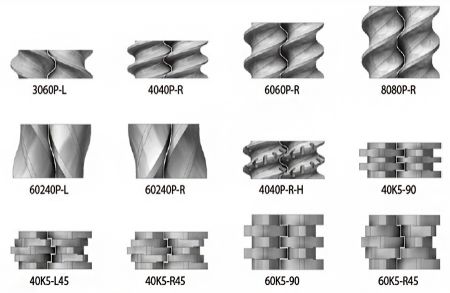

The parallel twin-screw extruder is capable of processing a wide variety of raw materials. By using two screws for mixing, it achieves optimal results, with the flexibility to adjust the screw configuration depending on the material. This versatility makes it suitable for various applications, including in the food, plastic, rubber, and chemical industries.

The parallel twin-screws in the extruder can be divided into two designs: co-rotating parallel twin screws and counter-rotating parallel twin screws. Co-rotating parallel twin screws rotate in the same direction, making them ideal for applications that require high mixing efficiency. On the other hand, counter-rotating parallel twin screws rotate in opposite directions, making them suitable for processes that require high shear forces.

Committed to Quality, Creating Value.

With 40+ years of experience, Ho Hsing has grown from OEM to a full-service company, guided by Japanese experts and driven by advanced technology.

Your Trusted Partner

We stand behind our products and are committed to resolving issues, ensuring full customer satisfaction.

Strict Quality Control

Our products undergo multiple checks during production to ensure accuracy and excellence in the finished results.

Professional Development Team

From OEM to a full company, we know the key components in industry and offer valuable advice to our customers.

Parallel Twin Screw | OEM/ODM Extrusion Components - HO HSING

With over 36 years of experience, HO HSING specializes in manufacturing Parallel Twin Screw, twin-screws, twin-barrels, and double-pillar hydraulic screen changers. Guided by our commitment to excellence, we provide OEM-quality precision parts with full customization support. ISO 9001–certified and equipped with Mitutoyo CMM from Japan, we ensure zero-defect delivery and complete quality control to boost productivity and cut costs.

Choose HO HSING extruder parts—from twin-screw/twin-barrel replacements to hydraulic screen changer, gear pump, static mixer, die plate, and pelletizing head solutions. As a Taiwan OEM/ODM factory, we offer custom machining, fast lead times, and global shipping—request a quote to optimize plastic extrusion output and reduce downtime.

Since 1984, HO HSING has manufactured high-quality twin-screws, twin-barrels, and double-pillar hydraulic screen changers for plastic extrusion. Backed by advanced technology and 36 years of OEM/ODM experience, we deliver precision extruder parts, full customization, and rigorous quality control to meet demanding production requirements.